Project

Project description

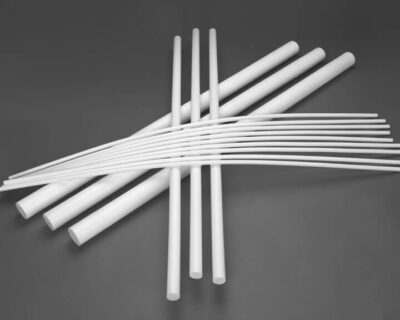

PTFE (polytetrafluoroethylene) molded rods are cylindrical components made from PTFE material through a molding process. PTFE is a highly versatile material known for its excellent chemical resistance, high-temperature tolerance, and low friction coefficient. PTFE molded rods are used in a wide range of industrial applications due to their unique properties.

The molding process used to create PTFE rods involves heating and compressing PTFE material into a specific shape using a mold. The resulting rods have a high degree of dimensional stability and consistency, making them ideal for precision applications. PTFE molded rods can be produced in various sizes and shapes, depending on the specific application requirements.

PTFE molded rods offer several advantages over other materials, such as their non-reactive nature with chemicals and ability to withstand extreme temperatures. They also have low friction coefficients, making them ideal for use in applications that require a high degree of lubricity. PTFE molded rods are often used in industries such as chemical processing, aerospace, and automotive manufacturing.

Overall, PTFE molded rods are a reliable and cost-effective solution for applications that require high chemical resistance, high-temperature tolerance, and low friction coefficients. Their versatility and customizable nature make them a popular choice in a wide range of industrial applications.

Project details

- Project: PTFE Molded Rod

- Category: PTFE Standard Stock Shapes

- Client: Spanhaus