Project description

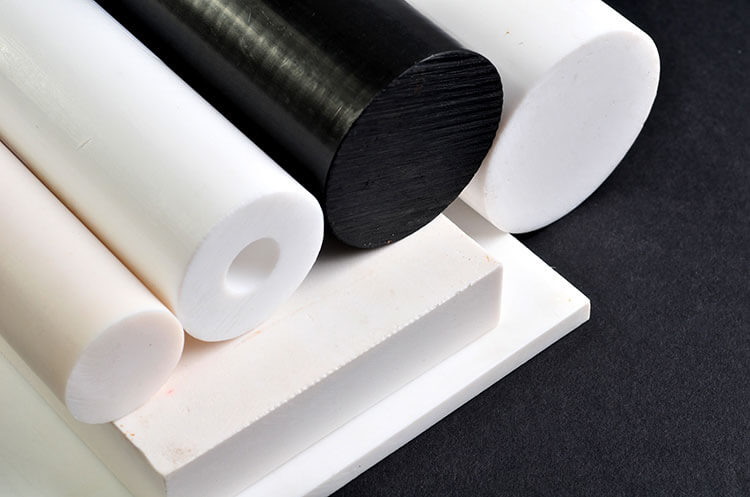

Expanded PTFE (ePTFE) sheet is a material made from PTFE resin that has been processed to create a highly porous and flexible sheet. The process involves stretching the PTFE material in a controlled manner, creating a network of microscopic fibrils that interconnect to form a highly porous structure. This structure gives ePTFE sheet its unique properties, such as excellent chemical resistance, low friction, high tensile strength, and the ability to conform to irregular surfaces.

ePTFE sheet is commonly used in applications that require a highly resilient and flexible material with excellent sealing and gasketing properties. It is also used in the medical industry as a biomaterial for various implants and surgical applications, as it is biocompatible and highly resistant to body fluids.

In addition to its versatility, ePTFE sheet is also highly customizable, with a range of thicknesses and pore sizes available to suit specific applications. It can also be laminated with other materials, such as adhesive backings or metal mesh, to enhance its performance in certain applications.

Overall, ePTFE sheet is a highly versatile and reliable material that can be used in a wide range of industrial, medical, and engineering applications, providing excellent performance and durability in even the most challenging environments.