Project

Project description

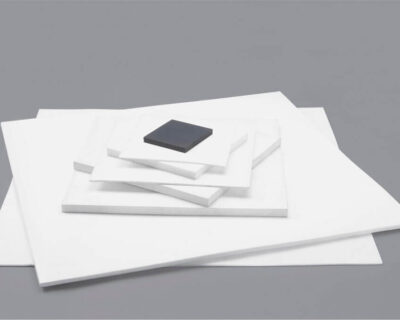

PTFE (polytetrafluoroethylene) skived sheets are thin, flat sheets made from PTFE material. The term “skived” refers to the process used to create the sheets, which involves slicing or cutting a block of PTFE resin into thin layers using a skiving machine. The resulting sheets have a smooth surface finish and high dimensional stability, making them ideal for a wide range of applications.

PTFE skived sheets are known for their excellent chemical resistance, low coefficient of friction, and high temperature tolerance. They are commonly used in applications that require a highly resilient and flexible material with excellent sealing and gasketing properties. PTFE skived sheets are often used in industries such as chemical processing, pharmaceuticals, and food and beverage production.

PTFE skived sheets are available in a variety of thicknesses and widths, and can be customized to suit specific application requirements. They can also be reinforced with other materials, such as glass fiber, to enhance their performance in certain applications.

Overall, PTFE skived sheets are a reliable and cost-effective solution for applications that require high chemical resistance, low friction, and high-temperature tolerance. Their versatility and customizable nature make them a popular choice in a wide range of industries.

Project details

- Project: PTFE Skived Sheets

- Category: PTFE Standard Stock Shapes

- Client: Construxive